PMDC Motors

A PMDC motor does not have a field winding on the stator frame, instead relying on PMs to provide the magnetic field against which the rotor field interacts to produce torque. Compensating windings in series with the armature may be used on large motors to improve commutation under load. Because this field is fixed, it cannot be adjusted for speed control. PM fields (stators) are convenient in miniature motors to eliminate the power consumption of the field winding. Most larger DC motors are of the "dynamo" type, which have stator windings. Historically, PMs could not be made to retain high flux if they were disassembled; field windings were more practical to obtain the needed amount of flux. However, large PMs are costly, as well as dangerous and difficult to assemble; this favors wound fields for large machines.

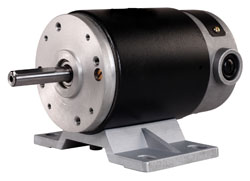

To minimize overall weight and size, miniature PM motors may use high energy magnets made with neodymium or other strategic elements; most such are neodymium-iron-boron alloy. With their higher flux density, electric machines with high-energy PMs are at least competitive with all optimally designed singly fed synchronous and induction electric machines. Miniature motors resemble the structure in the illustration, except that they have at least three rotor poles (to ensure starting, regardless of rotor position) and their outer housing is a steel tube that magnetically links the exteriors of the curved field magnets.

Features

- Suitable for continuous and intermittent duties.

- Used for both clockwise and/or counter clockwise operations

- Dual coated copper wire for enhanced performance

- Graded steel Stampings for higher efficiency

- Consistency in performance due to controlled in house magnetisation process

- Dynamically balanced armatures for vibration free operation

- Surge tested high reliable Armatures

- Available with or without Gear

- Compact in size with build in Gearbox

- Die cast casings and end brackets ensures quality & durability

- Protection : IP00/IP20/IP40

- Insulation : Class B/F

Available Ranges

| Output Watts | 18 to 370 W |

|---|---|

| Voltage | 12 to 240 V DC |

| FL Speed | 1,200 to 6,000 RPM |

| Torque | 0.03 to 3 Nm |

| Insulation Class | B and F |

| Duty | S1 (Continuous) and S2 ( Short duty) |

Applications

- Circuit breakers

- Medical equipments

- Laboratories

- Treadmill

- Solar fans

- Vane Pumps

- Dis connectors

- Ring main Units (RMU)

- Health fitness equipment

Specifications

| Model | RPM | Watts | HP | Volts |

|---|---|---|---|---|

| P101 | 1500 | 17 | 0.02 | 12 |

| P101 S15 | 6000 | 20 | 0.03 | 24 |

| P101 S2 | 10,000 | 30 | 0.04 | 36 |

| P101 S3 | 6,000 | 20 | 0.03 | 24 |

| P101 S4 | 4,000 | 24 | 0.03 | 12 |

| P101 S5 | 10000 | 20 | 0.03 | 24 |

| P101 S8 | 1,800 | 18 | 0.02 | 12 |

| P101 S8 | 1800 | 18 | 0.02 | 12 |

| P103 | 1,500 | 18 | 0.02 | 12 |

| P103 S1 | 1500 | 18 | 0.02 | 12 |

| P103 S2 | 1800 | 30 | 0.04 | 12 |

| P103 S3 | 1,800 | 18 | 0.02 | 12 |

| P103 S6 | 1800 | 18 | 0.02 | 12 |

| P103 S7 | 1800 | 30 | 0.04 | 12 |

| P201 | 5,000 | 120 | 0.16 | 24 |

| P202 | 5,000 | 120 | 0.16 | 36 |

| P203 | 5,000 | 120 | 0.16 | 42 |

| P203 S4 | 3000 | 80 | 0.11 | 48 |

| P203 S5 | 3,000 | 80 | 0.11 | 24 |

| P204 | 5,000 | 120 | 0.16 | 110 |

| P301 | 3,000 | 80 | 0.11 | 24 |

| P301 S1 | 10,000 | 80 | 0.11 | 180 |

| P301 S11 | 3,000 | 80 | 0.11 | 24 |

| P301 S5 | 6,000 | 80 | 0.11 | 36 |

| P302 | 1,800 | 120 | 0.16 | 24 |

| P302 S1 | 1,800 | 120 | 0.16 | 24 |

| P302 S11 | 3,000 | 140 | 0.19 | 24 |

| P302 S14 | 3000 | 120 | 0.16 | 110 |

| P302 S15 | 1,500 | 120 | 0.16 | 110 |

| P302 S15 | 1500 | 120 | 0.16 | 110 |

| P302 S16 | 1,800 | 180 | 0.24 | 36 |

| P302 S17 | 3,500 | 120 | 0.16 | 24 |

| P302 S2 | 3,800 | 90 | 0.12 | 190 |

| P302 S7 | 3,000 | 120 | 0.16 | 24 |

| P303 | 3,000 | 120 | 0.16 | 24 |

| P304 | 5,000 | 120 | 0.16 | 24 |

| P305 | 5,000 | 120 | 0.16 | 110 |

| P306 | 5,000 | 120 | 0.16 | 36 |

| P306 S2 | 5,000 | 120 | 0.16 | 36 |

| P306 S3 | 5,000 | 180 | 0.24 | 36 |

| P306 S4 | 5,000 | 180 | 0.24 | 36 |

| P308 | 5,000 | 120 | 0.16 | 42 |

| P308 S1 | 5,000 | 120 | 0.16 | 42 |

| P309 | 5,000 | 150 | 0.20 | 12 |

| P309 S1 | 6,000 | 150 | 0.20 | 24 |

| P309 S3 | 5,000 | 150 | 0.20 | 24 |

| P310 | 3000 | 80 | 0.11 | 24 |

| P401 | 3000 | 180 | 0.24 | 180 |

| P401 S1 | 4000 | 180 | 0.24 | 180 |

| P401 S11 | 3000 | 180 | 0.24 | 180 |

| P401 S17 | 1,500 | 180 | 0.24 | 24 |

| P401 S2 | 3,000 | 180 | 0.24 | 180 |

| P401 S4 | 3000 | 180 | 0.24 | 180 |

| P401 S8 | 3000 | 180 | 0.24 | 180 |

| P403 | 3,300 | 180 | 0.24 | 180 |

| P403 S10 | 1,300 | 60 | 0.08 | 220 |

| P403 S12 | 1,200 | 180 | 0.24 | 110 |

| P403 S5 | 3,000 | 180 | 0.24 | 180 |

| P403 S6 | 3,300 | 180 | 0.24 | 180 |

| P403 S7 | 4,500 | 180 | 0.24 | 180 |

| P403 S8 | 3,000 | 180 | 0.24 | 240 |

| P403 S9 | 3,400 | 180 | 0.24 | 240 |

| P404 S2 | 2000 | 235 | 0.32 | 220 |

| P405-24 | 1000 | 100 | 0.13 | 24 |

| P501 | 1,500 | 370 | 0.50 | 180 |

| P502-110 | 2,200 | 470 | 0.63 | 110 |

| P502-220 | 2,200 | 470 | 0.63 | 220 |